About the Sequence Numbering System

System assigning sequence to each part to manage products from arrival to shipment.

Upon arrival, a sequence number is automatically assigned to each part to perform inventory management.

In shipment, a GPS control number is assigned to the sequence number of each part, enabling tracing of whether the shipped item has been delivered to the delivery destination.

System Objectives

In order to check the consistency of inventory data, the system tracks the flow of each quantity from reception to dispatch based on reception and dispatch history, and checks discrepancies between the history and the number of items in stock. This enables tracing the stage where the discrepancies occurred, if any.

The flow of goods in and out can be checked in the following patterns.

- Sales from regular purchasing to delivery

- Reception processing of inventory items

- Dispatch processing of inventory items

- History of delivery sales in which non-inventory items were purchased at the time of sale and were shipped without being in stock

Utilization of Artificial Intelligence

How to use prediction models

- Using sequence data, perform artificial intelligence-based demand prediction and present the following prediction.

- Output a shipping prediction to allow customers to judge whether the target product number should be in-stock item.

- Through prediction data from artificial intelligence, enable optimization of the quantity of the stock item in stock.

Enable customers to check monthly artificial intelligence prediction data and actual data in comparison tables. - Using prediction data from artificial intelligence, enable suggestions for stocking items currently not in stock but are frequently shipped.

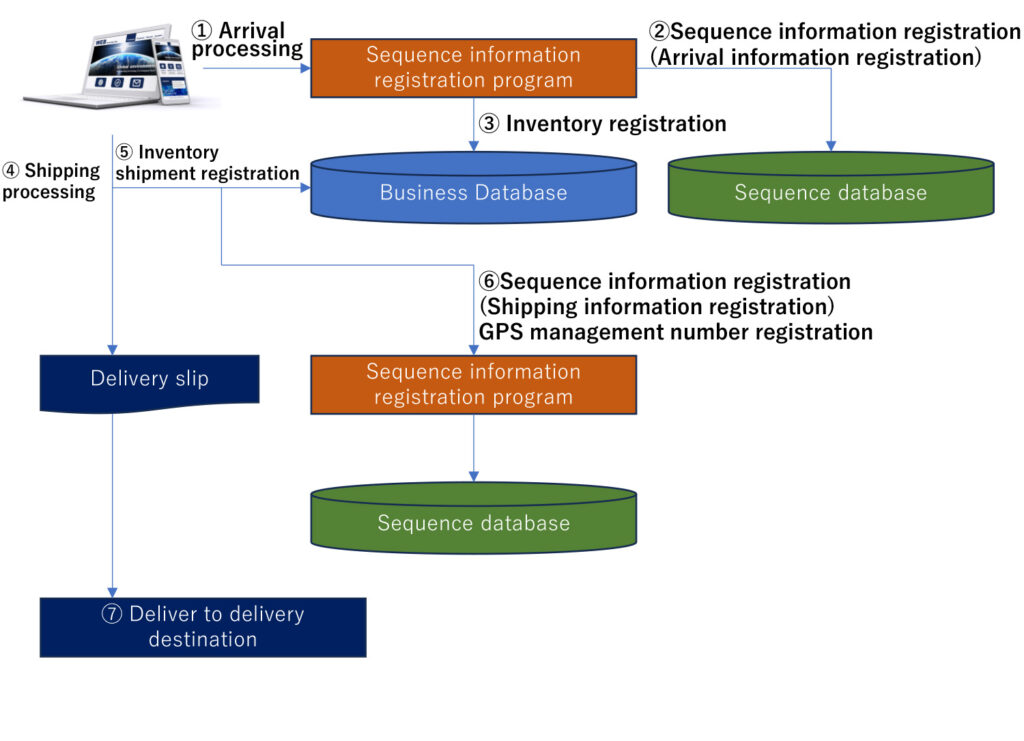

Simple Flow Diagram

Details

Processing numbers ① to ③ are in stock processing.

② Sequence information registration (arrival information registration): Assign a sequence number to each item and save sequence information in a database.

For sequence numbering, a sequence number is automatically assigned to each piece also for arrival in lots.

③ Inventory registration: Save inventory information into database.

Processing numbers ④ to ⑦ are in stock processing.

⑤ Inventory shipment registration: Information that inventory items have been shipped is saved in a database.

⑥ Sequence information registration (shipping information registration), GPS management number registration: Saves shipped flag into database for sequence number registered for shipping.

Add GPS information to sequence number and perform GPS tracking to delivery destination.

⑦ Delivery to delivery destination: When delivery is carried out to delivery destination, a delivery flag is saved in a database to complete GPS tracking.